MONITORING AND CONDITION

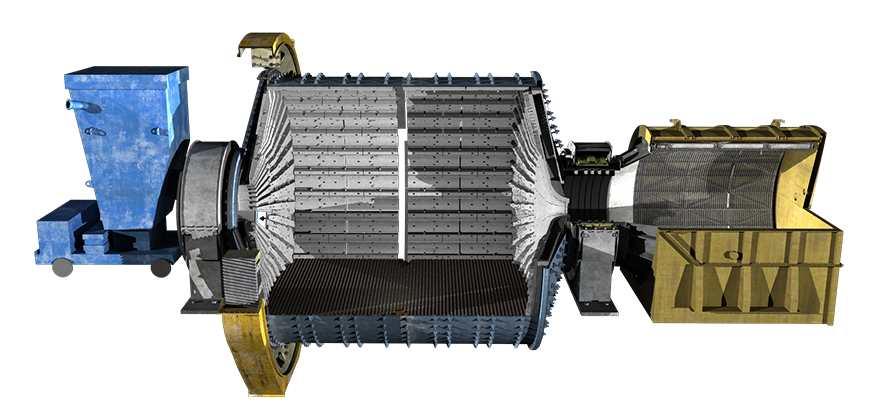

BALL AND SAG MILLS

WEAR MONITORING OF LINERS

LASER SCANNING METHODOLOGY

Measurement without Operator contact with the Equipment, provides a fast and efficient way to inspect and perform reverse engineering of complex parts and surfaces.

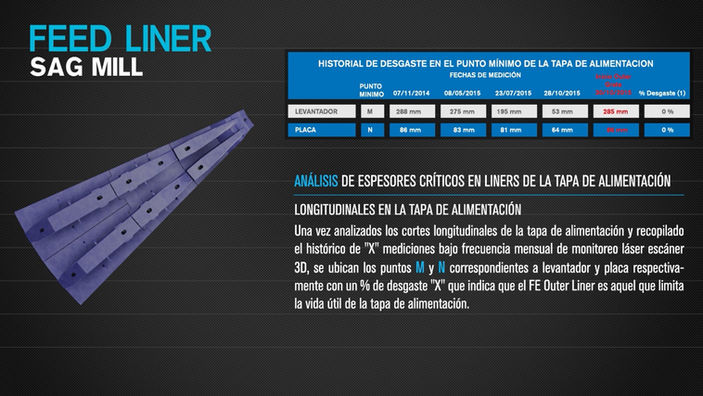

FEED LINER - SAG MILL / BALLS

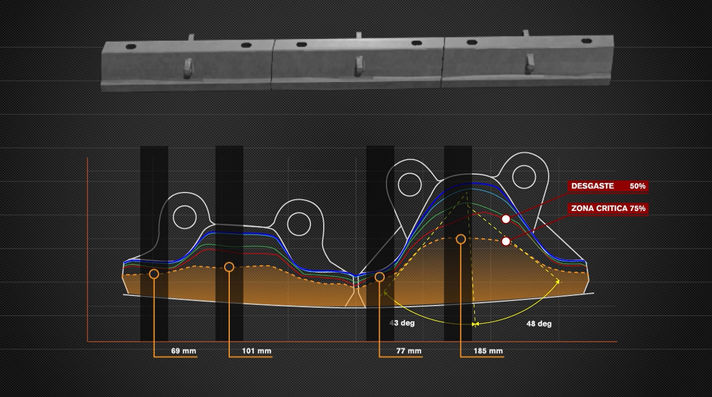

At INCAD SERVICE we carry out analyzes cladding, focusing in its thicknessescritics, preparing reports with data collected fromthrough of the useful life, each record is generated withlatest technologygeneration.

OBJECTIVE OF THE SERVICE

-

Generate baseline of equipment reliability.

-

Develop reports with wear history.

-

Deliver reports with critical areas of the equipment.

-

Operational reliability of large assets

DEM SIMULATION

Having the geometry of the linings in conjunction with databases of process variables, can automate the simulation tasks of particular operating scenarios. Being able to do it "programmatically" and without human intervention is the desirable condition for this stage of the project.

VIEW SCAN

-

The OnLine report with historical record of each survey

-

A forecast of the useful life of the coating

-

Component Comparison

-

saturation areas

-

Record Lifetime Calculation